From its 15 manufacturer titles in the NASCAR Sprint Cup Series to four overall wins at the 24 Hours of Le Mans, Ford Racing can trace much of its worldwide success back to a building in Dearborn, Michigan, that has served as its cradle of speed for more than seven decades.

First opened in the 1940s, Ford’s Dynamometer Lab has been home to the development of many of the Detroit automaker’s racing engines, including the Le Mans-winning 427 big block in the GT40s and the modern-day, production-based 3.5-liter EcoBoost V6 that powers the Ford factory Daytona Prototypes fielded by Chip Ganassi Racing with Felix Sabates and Michael Shank Racing with Curb/Agajanian in the TUDOR United SportsCar Championship.

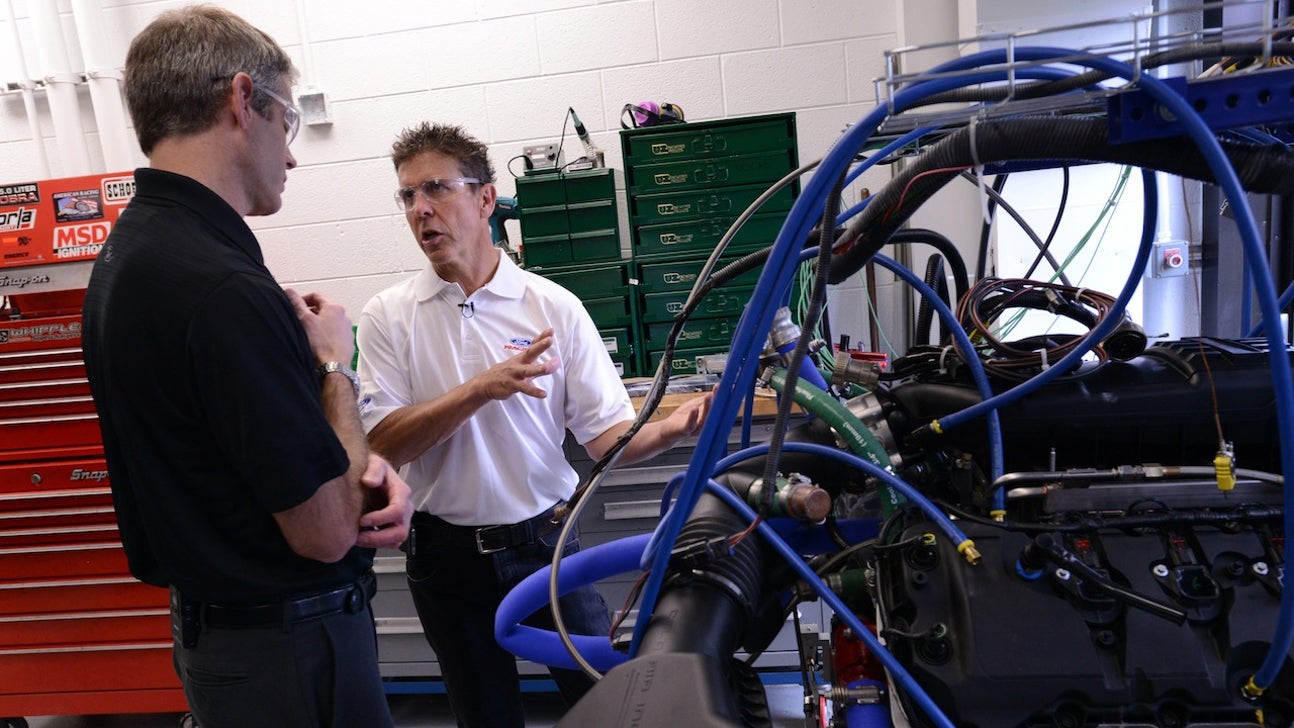

"You can feel the history of racing at Ford when you walk down the halls of the Dyno Lab," said Jamie Allison, Director of Ford Racing. "What our racing engineers do there, working side-by-side with production engineers, is a big part of the foundation of our TUDOR Championship program and definitely something that makes us unique among manufacturers."

The majority of Ford Racing’s engine development is undertaken at “17G,” one of 110 dyno cells in the building, which are all referred to by cell number. 17G was commissioned in 1996 for The Ford Formula One and IndyCar engine programs and was the first of its kind for Ford.

According to Ford Racing powertrain engineer Dave Simon, roughly 20 to 30 engines are put through their paces on the dyno every year, including those used for NASCAR and IMSA competition and the occasional production engine. Each test lasts about two weeks.

“There’s a lot of history to developing race engines (in the same building as production engines) in Dearborn that I don’t think anyone else can claim,” said Simon. “There’s a big legacy to it. When you walk into the building, what you see on the walls are historic photos from that building from the 1940s, 1950s, 1960s, 1970s, 1980s… We’re just continuing that tradition.”

The dyno provides a virtual test track for the engines, as they’re able to complete full simulation runs for any circuit, while also simulating real-life track conditions and climate, including ambient temperature and humidity… and even the occasional missed shift.

While Ford Racing engineers typically have 17G running eight-hour shifts a day, for five a days a week, it’s only one of many cells in the expansive Dyno Lab, which solidifies the manufacturer’s racing program’s relevance to production cars.

“We could be running next door to anything from 7L diesel to 5L Coyote engines,” said Simon. “We’re developing a 3.5L EcoBoost race engine right down the hall from the 3.5L production engine.”

As the pair of Ford EcoBoost-powered Riley DPs from Chip Ganassi Racing and Michael Shank Racing tackle Canadian Tire Motorsport Park for the first time this weekend, be rest assured the engines have racked up plenty of mileage — in Dearborn — for the task at hand.