Maximizing the efficiency of EcoBoost

In the ultra-competitive world of sports car racing, development never stands still, with manufacturers often working year-round to extract the maximum performance and efficiency out of each car.

For Ford Racing, which entered this year’s TUDOR United SportsCar Championship with brand-new EcoBoost-powered engines, optimizing the powerful, yet compact V6 twin-turbo to the DP chassis has been one of the recent focal points.

While having scored victories in the 12 Hours of Sebring and on the streets of Long Beach with partner team Chip Ganassi Racing with Felix Sabates, the Dearborn, Mich.-based engineering staff has been looking for ways to make further gains on the track.

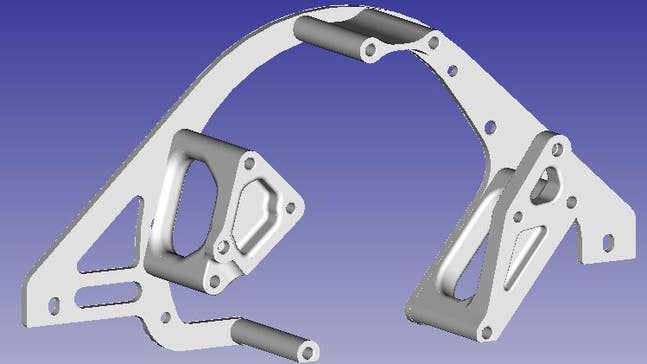

One of the recent developments that will debut on both the No. 01 Ganassi and No. 60 Michael Shank Racing with Curb/Agajanian Ford EcoBoost DP entries in this weekend’s Lone Star Le Mans at Circuit of The Americas are revised engine mounting components.

With Ford engineers having less than six months to develop the EcoBoost powerplant for TUDOR Championship competition, the design of the mounting system included in the race car was not optimized for the production-based engine’s unique architecture, adding unnecessary weight.

“We came into the TUDOR Championship this year with an all-hands-on-deck approach,” said Mark Rushbrook, Ford Racing motorsports engineering manager. “We knew there would be a learning curve when we decided to grow our effort in sports car.

“One of the challenges we immediately faced was adapting the EcoBoost V6 twin-turbo to the Riley DP frame, and all of the boxes we needed to check that came with that. But to us, it was worth making the change to EcoBoost power.”

Some issues were fixed immediately, while others were tagged to be solved as the season went on with support by engineers from the existing Ford College Graduate and new Motorsports Technology Exchange programs. This year Ford Racing and Ford Motor Company launched a cross-training program that sends production engineers into the racing program for hands-on experience that can’t be replicated anywhere else. The cross-training results in sharing knowledge fluidly between Ford and Ford Racing.

(Old part): With Ford engineers having less than six months to develop the EcoBoost powerplant for TUDOR Championship competition before its debut, the design of the mounting system was not optimized for the production-based engine’s unique architecture, adding unnecessary weight.

Remarkably, according to Ford Racing Development Engineer Eric Damphousse, the new engine mount spacers, optimized by advanced CAE analysis, offers a 40 percent reduction in weight of the original parts. And with the Riley-based DPs having been slightly over the 2,290-pound minimum weight requirement, it results in a huge savings.

The parts were successfully tested on the Michael Shank Racing car for the first time last week at Mid-Ohio, without sacrificing the component’s durability or stiffness.

Now, both of the factory-backed Ford Prototype class entries are set to benefit from the weight savings in Saturday’s penultimate TUDOR Championship round of the season, as Ganassi and Shank look to close out the season on a high note.