Five things you didn't know about how goalposts get made

Last year in the NFL, 35 different kickers made a total of 1,262 extra points and 863 field goals over the course of the regular season, and chances are good that not once did any of them -- or any of us watching -- think twice about the goalposts those kicks sailed through.

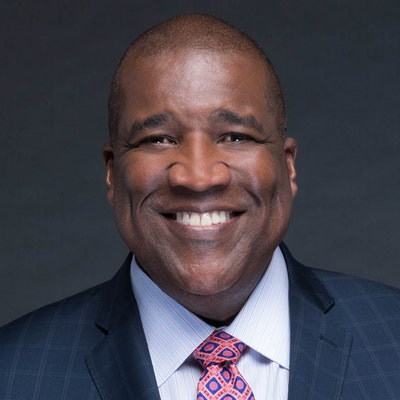

For David Moxley, however, goalposts are pretty much always on the brain. As the director of sports construction sales for Sportsfield Specialties, Moxley's job, in part, is to make sure the goalposts his company manufactures are doing exactly what they're designed to do: stand up straight, hold up to the elements and only get in the way when they're deflecting slightly errant kicks.

From high school to college to the pros, goalposts are largely taken for granted -- overlooked like other critical field components such as hash-marks and pylons -- but the process by which the posts are made is quite sophisticated. So let's take a closer look at one of the league's most underappreciated, yet critical pieces of infrastructure. Here are five things you might not know about the process:

1. Each individual goalpost takes approximately 15-18 hours to make.

Sportsfield Specialties is the NFL's largest supplier of goalposts, with their product in 23 of the league's 31 stadiums -- not to mention countless college and high school fields -- and at the company's factory in Delhi, N.Y., approximately 40 metal workers produce a total of 400 to 450 sets of goalposts per year. The company also has a facility in Salisbury, N.C., where "soft goods," such as goalpost padding, are made.

A typical goalpost starts as four straight, extruded pipes. One of those pipes is cut to size, then bent to shape in roughly seven to 10 minutes using a computerized rolling machine to create the "gooseneck" that forms the base. (Before 1967, the NFL used an H-style goalpost, which was about as aesthetically pleasing as it was safe for players.) The NFL's standard offset is six feet, though some schools at lower levels use eight-foot offsets to allow soccer goals to fit fully underneath the structure.

Meanwhile, the other three pipes are cut to size before they go through several steps of milling and welding, attaching joints and other components to prepare them for installation on site.

2. A standard goalpost weighs about 500 pounds.

At Sportsfield Specialties, the gooseneck and crossbar are made of dense schedule 40 aluminum, while the uprights are made of a lighter 1/8-inch wall aluminum.

Once it is built, a goalpost is secured into the foundation using either a ground sleeve or a base plate depending on the stadium, with the base customized to each facility for which goalposts are being built. Teams or schools can hire a contractor or installer to set them up, or they can just do it themselves.

The latter option is one of the reasons Sportsfield uses aluminum in its goalposts as opposed to steel, which is still the metal of choice for some goalpost manufacturers. At many stadiums, the field is used for concerts and other events when football isn't being played, so the ability to remove and replace the goalposts easily is crucial to the grounds crew.

3. Goalposts are engineered to withstand winds up to 115 miles per hour.

Obviously, the companies that make goalposts would rather fans didn't try to rip them out of the ground -- if for no other reason than because, at 500 pounds apiece, goalposts could easily do serious damage if they landed on one of the people below.

"Like anything, if you put too much weight on it, it's going to fall to the ground," Moxley said. "The first concern is obviously everybody's safety. We don't want anyone climbing on anybody's goalposts, for that matter, which I think is why the NCAA and NFL have all instituted fines if people access their field. But there's probably not a great answer for (how easy they are to tear down). It's going to vary by manufacturer and vary by material and foundation sizes, those types of things."

When goalposts do go down, or when they need to be replaced for other reasons, new ones don't exactly come cheap -- unless you crowdfund the replacement, of course -- and the price ultimately depends on what bells and whistles the client wants to include. (There are some that can be spun around in place, and others that can be raised and lowered using hydraulic pumps, for example.)

Fortunately, once installed, the goalposts tend to last as long as a stadium wants them to. Weather can sometimes expedite that timeline, but they are usually only replaced when teams make other upgrades to the stadium or playing surface.

"They probably last much longer than any of us would expect, minus the paint, which is always going to have some fade issues over time, and all of the things associated with mother nature that could hurt any product out in the field," Moxley said. "So there is normal wear and tear, but as long as they can stand up to windload, they're going to be fine for a very long time."

5. Prior to this season, every stadium in the NFL had to have new goalposts made.

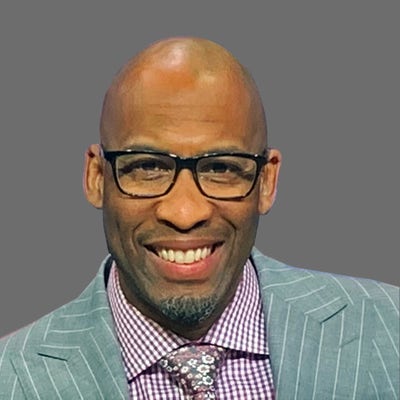

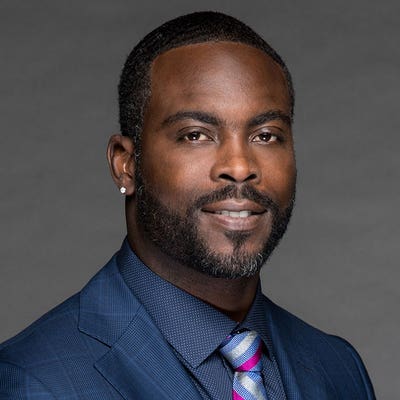

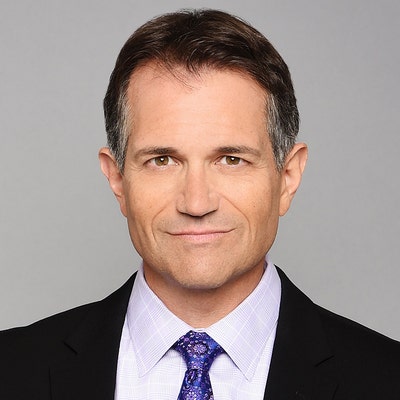

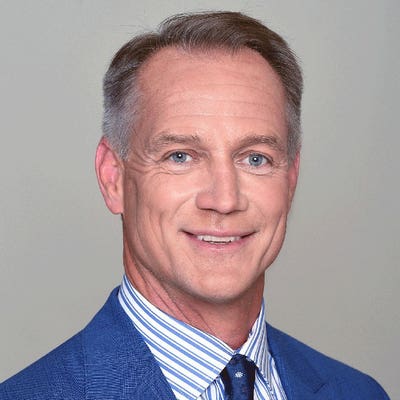

Sportsfield had to craft all new goalposts for each of its NFL clients after the league voted to replace the standard 30-foot uprights with 35-foot uprights. The change was referred to as the "Tucker Rule" by some, as it was thought to be inspired by Justin Tucker's controversial game-winning field goal in a 2012 meeting between the Ravens and Patriots.

The league passed the proposal to change the goalposts on March 26, and gave Sportsfield a completion date of Aug. 1, no easy task for Moxley and his team.

"It wasn't as simple as just putting five more feet on an upright; you had to go and re-engineer everything," Moxley said. "So that was not only a unique challenge, but it had to be done in a timely fashion to get it done by the NFL-imposed deadline. It was a scramble to go to the stadium, get the outside measurements, meet with people and come back and make custom goalposts in almost every case."

Justin Tucker's controversial game-winning field goal for the Ravens in a 2012 game against the Patriots spurred the league to add five yards of height to goalposts.